CONCEPTUALIZING

It is one thing to talk about design and décor but seeing is believing. That is one of the reasons Nesma Orbit starts every project with a detailed conceptualization of the client’s job.

After receive a drawing, perhaps even a blueprint, of the space to be treated, Nesma Orbit prepares a concept drawing and a presentation board. The presentation board displays the materials that Nesma Orbit believes are the best to use on the project. Concept drawings show the project in 2-D as well as in 3-D, computer-generated renderings, leaving no doubt as to the project’s ultimate appearance

SITE MEASUREMENTS

Once a decision on materials and products is made, Nesma Orbit sends its consultant to conduct on-site measuring in order to verify the measurements on the original drawings received from the client. As is often the case, structures may have changed since the original drawings were made, making it vital that every detail of the physical space be marked and measured. The new measurements will be used to create an “as-built” drawing to the client.

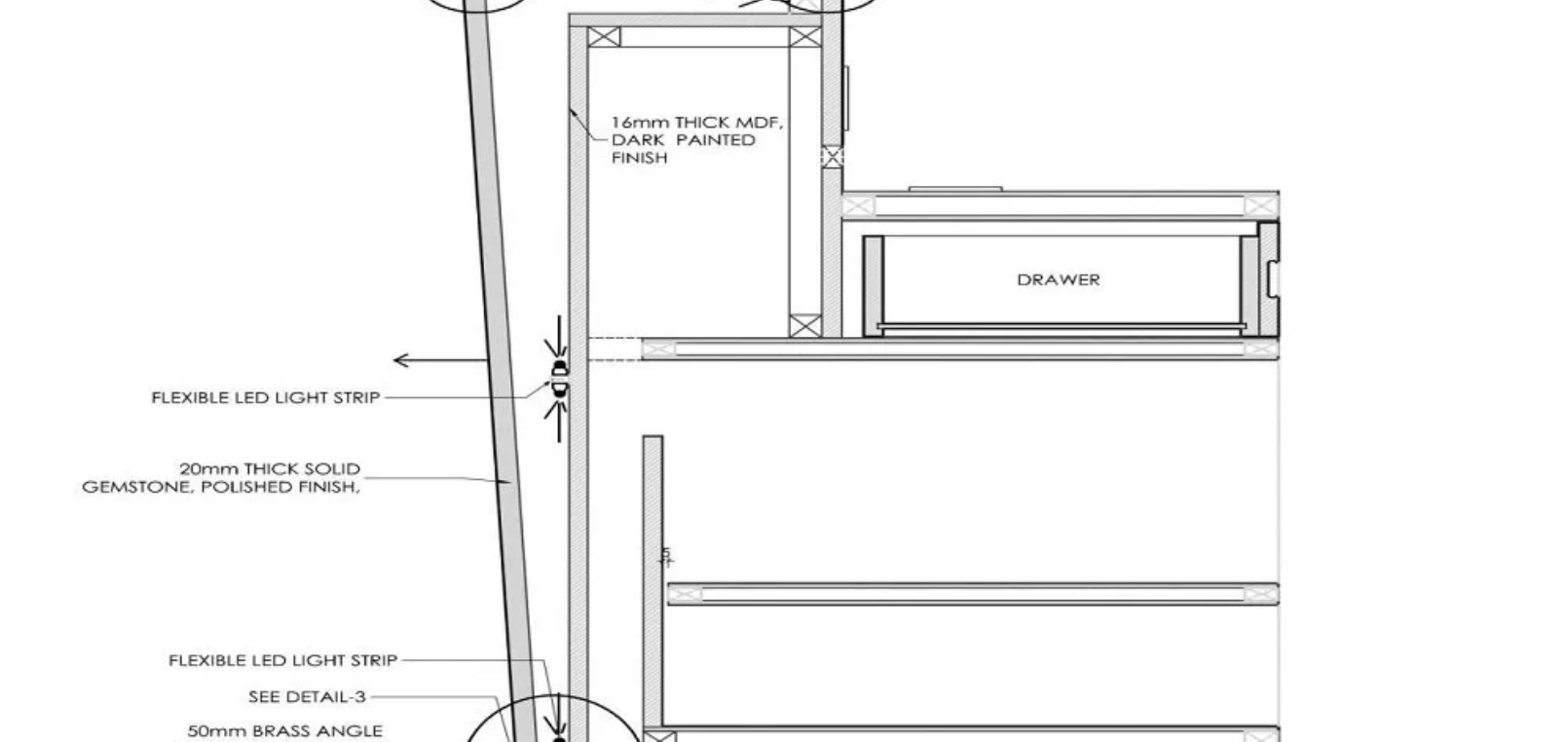

DETAILING

The last stage of Nesma Orbit’s preparation services, Detailing and Drawing, involves drawings that show every detail of the physical structure of the material to be installed as well as measurements of the overall installation. This involves not only identification of the material to be used, its thickness, its finish and means of attachment, but also exact measurements of height, width and depth of both components and the entire structure.

FACTORY

Nesma Orbit operates its own factory dedicated to producing the right size and cut of all of our products. Not only can we cut stone to standard and customized sizes and shapes, we can do the same for thickness, as well. We accomplish this using manually operated saws, digitally programmed saws and water jets. We also employ a Tumbling Machine that is capable of antiquing pieces of marble.

CNC 5 Axes

Machine used for engraving and shaping blocks of stonein to 3-dimensions such as sculptures, bathtubs, water basins and much more.

Profiling Machine

A piece of equipment for stone skirting, profiling and dado with exquisite detail.

Edge Polishing Machine

Used for profiling all stone edges with more than 20 different profiles.

Polishing Machine

The adjustable polishing machine is capable of bringing out just the right kind of sheen from any type of stone that we use.

Bridge Cutter

Controlled digitally, the bridge cutter is used only for large slabs of stone, cutting to standard sizes or to the unique demands of any job.

Five-Meter Saw 1

Operated manually, our five-meter saw is designed to cut small-sized slabs. It is also equipped with a laser for profile cutting for thickness.

Five-Meter Saw 2

Also manually operated, this second five-meter saw does not utilize a laser and is used only for small-sized slabs.

Waterjet Machine

Waterjet machines using water pumps are perfect for creating corporate logos in decorative designs on walls or inlaid into floors, countertop parts, faucet and sinkholes as well as a smoother radius off sharp edges of slabs cut with saws.

Tumbling Machine

By placing small marble items in the vibrating water of the tumbling machine, we are able to create an antique effect on their surfaces.